Experience with Layer FIT! concept

Poultry farmer J. Rama was one of the first poultry farms in Portugal to implement the Layer FIT! concept. Layer FIT! is based on the principle that, in an egg-producing poultry farm, all factors are interrelated and mutually influence each other. What we do in a layer’s first weeks of life impacts its whole productive life. That is why we use the metaphor of Newton’s cradle to represent the chain of elements that influences the different stages of a layer’s life.

History of the company

J. Rama was founded by the father, Joaquim Rama, over 50 years ago. The company had 1,500 barn hens when it started in the 1960s. It later increased to 10,000 hens during the 1970s, with the introduction of battery farming. The company has since grown gradually, and today J. Rama has 100,000 laying hens and around 35,000 rearing hens, in facilities that meet all European Union requirements. It produces between 6,000 and 7,000 dozen eggs per day and the company has seven employees.

The key to the company’s success

Mr Jorge Rama attributes his success in poultry farming to 3 main factors:

- They rear their own chicks from just a day old, controlling the genetics, nutrition, handling and vaccination programme of the future layers: “rearing is the key to successful production, in terms of egg production and quality (size, shell, colour) and in terms of health (dirty eggs or eggs with blood spots). Rearing is essential”.

- They invest in good facilities, that provide the hens with adequate temperature conditions, a peaceful environment, constantly available feed and good-quality water.

- They give their birds a wholesome feed, with a good balance of protein and energy, amino acids and pigments, and balance the feed according to each stage of production. “They mustn’t eat too much, as this influences production costs, but they also mustn’t eat too little, as this affects the size and shell of eggs, the laying and the persistence of laying. The eggs are what the hens eat,” says Mr Jorge Rama.

Mr Rama also highlights that having a diverse client portfolio and avoiding dependency on just one client is an important factor in their success. The eggs produced by J. Rama are distributed to wholesalers (approximately 50 to 60%) , to bakery industries and small supermarkets (approximately 35 to 40%) and the remaining 5 to 10% is intended for the pasteurisation industry (through Derovo, in which the company has a small share).

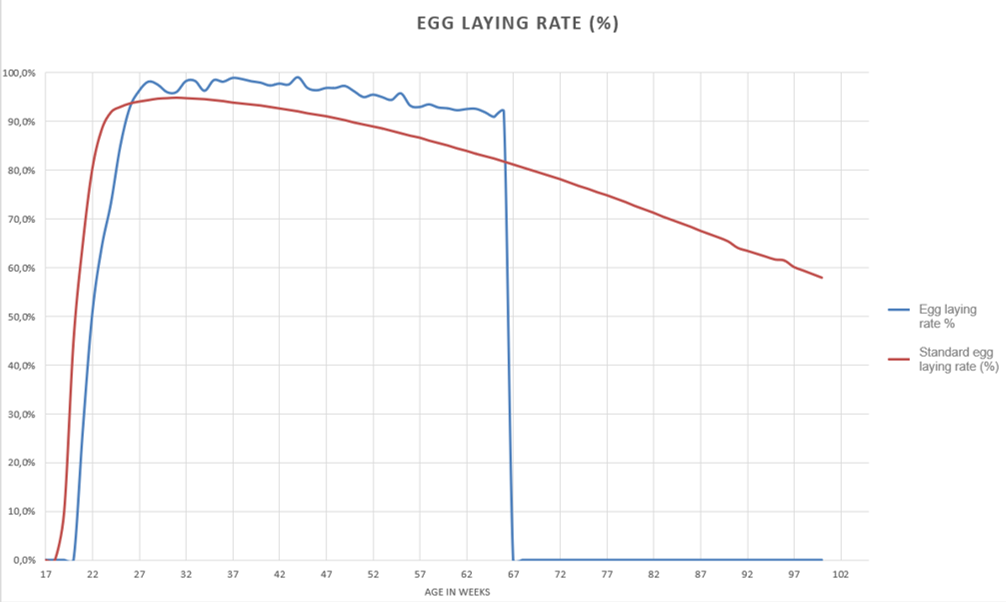

Experience with De Heus

Jorge Rama is delighted with De Heus. He is very satisfied with the performance level of the hens, as well as the relationship with the people from De Heus. The results couldn’t have been better; the flock’s performance has been excellent, both in terms of egg laying rate and the egg mass produced. The eggs have a good size and shell quality, maintaining an optimum laying persistency.

“This has been one of the best flocks of my life,” Mr Jorge Rama told us. Layer FIT! is based on the principle that, in an egg-producing poultry farm, all factors are interrelated and mutually influence each other. What we do in a layer’s first weeks of life impacts its whole productive life. That is why we use the metaphor of Newton’s cradle to represent the chain of elements that influence the different stages of a layer’s life.

“This has been one of the best flocks of my life”

The evolution of the industry

The poultry industry and egg production are popular at the moment. There have been a lot of media reports about the benefits of eating eggs, which has helped the industry. The market has been able to absorb the increased supply over the last few years and prices have remained relatively stable. However, the competition from North African countries with fewer environmental, health and animal welfare restrictions and requirements, is putting the industry under pressure and threatening its sustainability.

Cages or alternative systems?

Although cage systems could be improved, they continue to be the best system in terms of animal welfare (healthy, calm, well-conditioned and controlled hens, low mortality rate) and labour productivity. In alternative systems, hens may have a large area to roam (when they have access to it), although they tend not to move too far away for fear of predators (foxes, weasels, rats, birds of prey). It is more difficult to handle the hens, to collect eggs from the ground, to control diseases and the final product is not always better in terms of health (it can be quite the contrary). Production costs are higher, so end consumers should be able to choose what kind of eggs to consume, instead of the legislation imposing the use of alternative systems.

If you would like to know more about the Layer FIT! concept for laying hens, click here.